We're thrilled to announce our participation in the 2025 China International Sewing Machinery & Accessories Show (CLSMA 2025)! As a leading innovator in sewing equipment, we're excited to showcase our latest advancements at Booth W5-D26 in Hall W5.

📅 Event Details:

Date: September 24-27, 2025

Venue: Shanghai New International Expo Centre

Our Booth: W5-D26, Hall W5

Discover cutting-edge sewing machines, intelligent automation solutions, and sustainable technologies designed to elevate your production efficiency. Whether you're in apparel manufacturing, textiles, or beyond, this is your chance to explore how our products can transform your operations.

We cordially invite industry professionals, partners, and potential collaborators to visit us. Let's connect, discuss trends, and forge new opportunities!

Contact us at 13429656680 for more information or to schedule a meeting.

#CLSMA2025 #SewingMachinery #Innovation #ShanghaiExpo #GuoLingMachinery

See you there! 🚀

We are thrilled to share an in-depth look at the full production process of our cutting-edge GL-WX-300 sewing machine, designed specifically for ultra-wide flat slings. This video showcases the seamless workflow, precision engineering, and innovative features that make the GL-WX-300 a game-changer in the industry. From material preparation to the final stitch, witness how our technology ensures unmatched quality and efficiency. Explore the future of sling manufacturing with us and see why the GL-WX-300 is the preferred choice for professionals worldwide.

At Zhejiang Guoling Intelligent Technology, we’re proud to introduce the Compact Strap Winder, a state-of-the-art solution designed to redefine efficiency in strap processing. This compact machine is equipped with a 750W energy-efficient motor, offering adjustable speeds up to 2000 RPM and exceptional shutdown stability, making it a perfect fit for modern production lines.

Versatile and reliable, the Compact Strap Winder effortlessly handles semi-finished flat straps as well as finished products like ratchet straps and lifting slings. Its space-saving design ensures seamless integration into facilities of any size, while its energy-efficient technology minimizes costs without sacrificing performance.

Our latest video showcases the machine’s advanced features and demonstrates its precision in real-world applications. Whether you’re in logistics, manufacturing, or material handling, the Compact Strap Winder is engineered to optimize your workflow and deliver consistent results.

Ready to experience the future of intelligent manufacturing? Contact Zhejiang Guoling Intelligent Technology today to schedule a demo or learn more about how the Compact Strap Winder can elevate your operations.

Discover the GL-G3020 Rotary Hook Industrial Sewing Machine, engineered for precision and efficiency in webbing and binding strap production.

Precision Stitching: Delivers clean, consistent, and aesthetically pleasing seams for professional-grade results.

High-Speed Performance: Optimized for fast operation, maximizing productivity without compromising quality.

Robust Stability: Built for durability and reliable performance, ensuring seamless operation in demanding industrial environments.

📹 Watch our demo video to see the GL-G3020 in action and experience the innovation behind Zhejiang Guoling Technology’s industry-leading solutions.

Contact us today to learn how the GL-G3020 can transform your production line!

#IndustrialSewing #PrecisionEngineering #GuolingTech

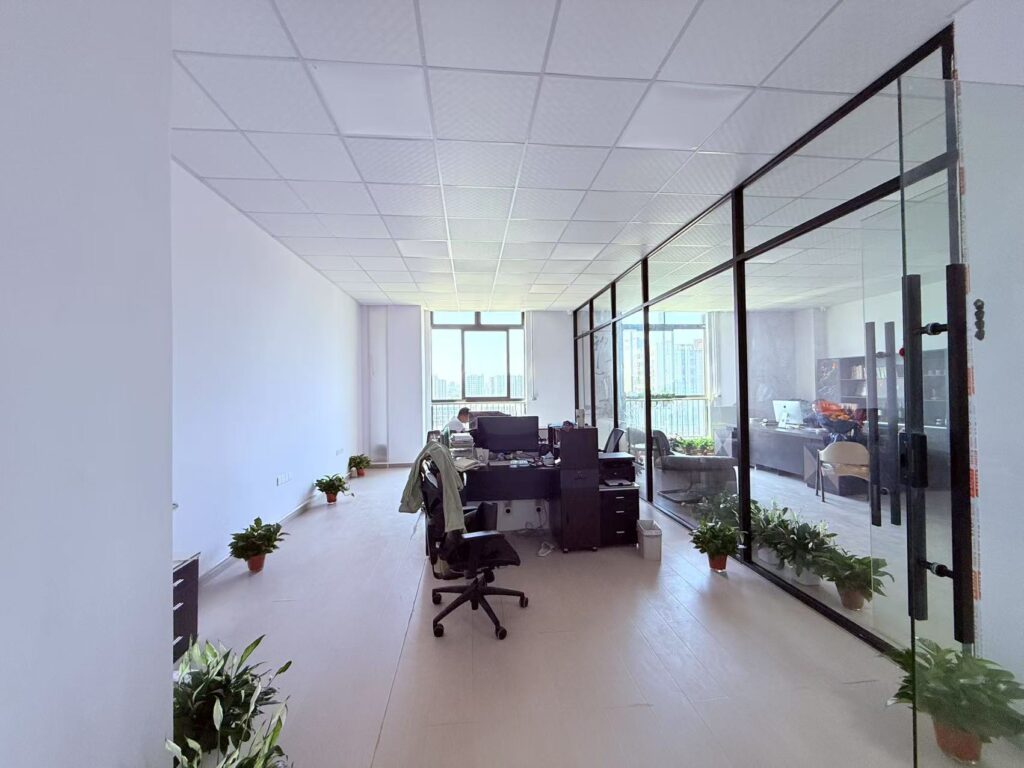

We’re excited to announce the launch of our brand-new office space — a dynamic environment designed to inspire innovation, collaboration, and growth.

From sleek workstations to open-concept meeting areas, every detail has been thoughtfully curated to support both productivity and well-being. Natural light floods the space, blending seamlessly with modern design elements that reflect our company’s vision and values.

This move marks a significant milestone in our journey, and we couldn’t be more thrilled to welcome our team — and visitors — into this inspiring new home.

Stay tuned as we settle in and continue pushing boundaries, together.

In today's fast-paced manufacturing industry, efficiency and productivity are key factors in determining the success of a business. One area where automation has made significant strides is in the field of industrial sewing. Automated sewing solutions offer numerous benefits that can help businesses streamline their operations and improve their bottom line.

One of the biggest advantages of automated industrial sewing solutions is the significant increase in productivity they offer. Automated machines can perform tasks at a much faster rate than manual sewing, allowing businesses to produce more products in less time. This increased productivity not only helps meet customer demands but also allows businesses to take on larger orders and expand their operations.

Furthermore, automated sewing machines can operate continuously without the need for breaks or rest, resulting in uninterrupted production and further boosting productivity. This can be especially beneficial for businesses that operate on tight deadlines or have high-volume production requirements.

Automation in industrial sewing ensures a higher level of quality and consistency in the finished products. Automated machines are programmed to perform precise and accurate stitches every time, eliminating the risk of human error. This consistency in stitching results in products that are uniform in appearance and meet the required quality standards.

In addition, automated sewing machines can be equipped with advanced sensors and monitoring systems that detect any issues or defects in the stitching process. This allows for immediate intervention and correction, ensuring that only high-quality products are produced.

While the initial investment in automated industrial sewing solutions may be higher than traditional manual sewing methods, the long-term cost savings can be significant. Automated machines require less labor, as they can perform tasks that would otherwise require multiple operators. This reduction in labor costs can result in substantial savings for businesses.

Furthermore, automated sewing machines are designed to be highly efficient, minimizing material waste and reducing the need for rework. This not only saves on material costs but also reduces the time and resources required to fix any mistakes or defects.

Automated industrial sewing solutions offer a high level of flexibility and adaptability to meet the changing needs of businesses. These machines can be programmed to perform a wide range of stitching patterns and styles, allowing businesses to easily switch between different products or designs without the need for extensive retooling or reconfiguration.

Additionally, automated sewing machines can be integrated into existing production lines, making it easier for businesses to incorporate automation into their operations without disrupting their workflow. This flexibility ensures that businesses can quickly respond to market demands and stay competitive in a rapidly evolving industry.

Automated industrial sewing solutions offer numerous benefits for businesses in terms of increased productivity, improved quality, cost savings, and flexibility. By embracing automation, businesses can streamline their operations, meet customer demands more efficiently, and stay ahead of the competition in the fast-paced manufacturing industry

As technology continues to advance, industries across the board are finding innovative ways to streamline their processes and increase efficiency. The textile industry is no exception, and one area where automation has made a significant impact is in industrial sewing. Automated industrial sewing solutions offer numerous advantages over traditional manual sewing methods, making them a game-changer for manufacturers.

One of the primary benefits of automated industrial sewing solutions is the significant increase in productivity. Automated machines can perform tasks at a much faster rate than human operators, allowing manufacturers to produce more garments or textiles in a shorter amount of time. This increased productivity not only leads to higher profits but also allows businesses to meet tight deadlines and fulfill large orders more efficiently.

Manual sewing can be subject to human error, resulting in inconsistencies in the final product. However, automated industrial sewing solutions offer a level of precision and accuracy that is difficult to achieve manually. These machines can perform intricate stitching patterns with consistent tension, ensuring that every garment or textile produced meets the highest quality standards. This consistency in quality is crucial for maintaining customer satisfaction and building a reputable brand.

While the initial investment in automated industrial sewing solutions may be higher than traditional sewing methods, the long-term cost savings are significant. Automated machines require less labor, reducing the need for a large workforce and the associated costs such as wages, benefits, and training. Additionally, these machines are designed to be energy-efficient, further reducing operational costs. Over time, the cost savings achieved through automation can outweigh the initial investment, making it a financially sound decision for manufacturers.

Manual sewing can be physically demanding and repetitive, leading to potential health issues for workers. Automated industrial sewing solutions alleviate these concerns by taking over the repetitive tasks and reducing the physical strain on employees. This not only improves worker safety but also enhances job satisfaction and reduces the risk of workplace injuries. By implementing automated sewing solutions, manufacturers can create a safer and more comfortable working environment for their employees.

Automated industrial sewing solutions offer a high degree of flexibility and customization options. These machines can be programmed to perform various stitching patterns, allowing manufacturers to cater to different design requirements and customer preferences. Additionally, automated machines can easily switch between different products, reducing downtime and increasing overall efficiency. This flexibility and customization capability give manufacturers a competitive edge in meeting the ever-changing demands of the textile industry.

Automated industrial sewing solutions have revolutionized the textile industry by offering increased productivity, consistent quality, cost savings, improved worker safety, and flexibility. As technology continues to advance, these automated machines will likely become even more sophisticated, further enhancing their benefits. Manufacturers who embrace automation in their sewing processes will not only stay ahead of the competition but also position themselves for long-term success in a rapidly evolving industry.

Welcome to JS Automation Co., Ltd.!

Thank you for reaching out. We specialize in industrial sewing machines, tape cutting machines, and tape winding machines. Whether you need help with a specific product or just have a question, we're here to assist you. Let us know how we can help!

🟢 Online | Privacy policy

WhatsApp us